Accessible Piping Makes Ladner Townhouse Replacement Efficient

When Eric learned that neighbors in his Ladner townhouse complex had replaced their Poly B plumbing, he scheduled his own assessment. The inspection revealed good news: his unit’s plumbing configuration allowed for “piping only” replacement without extensive drywall work. While neighboring units required full remediation including drywall restoration, Eric’s accessible layout meant a more efficient scope—demonstrating how individual circumstances shape project requirements even within identical-looking townhouse buildings.

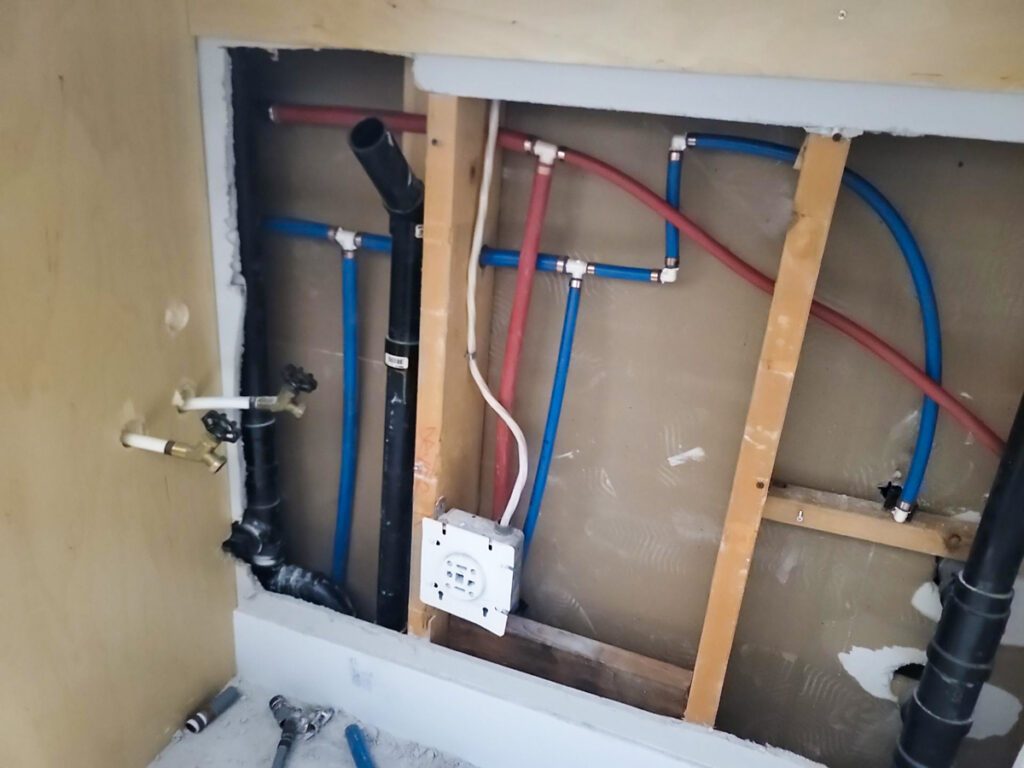

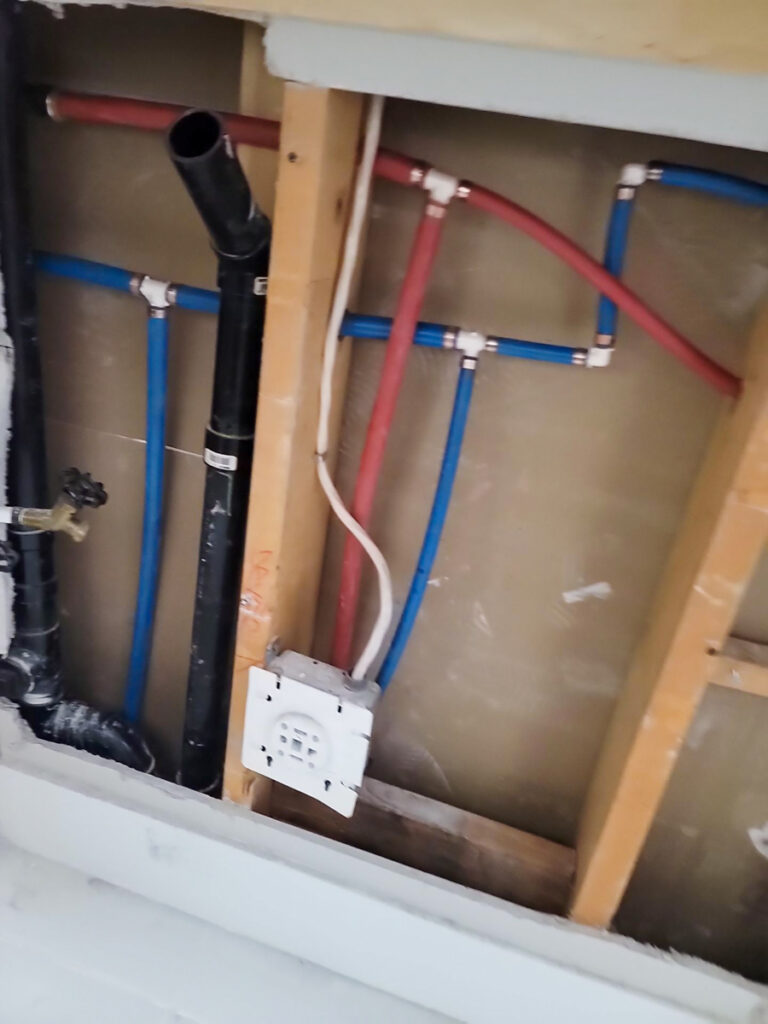

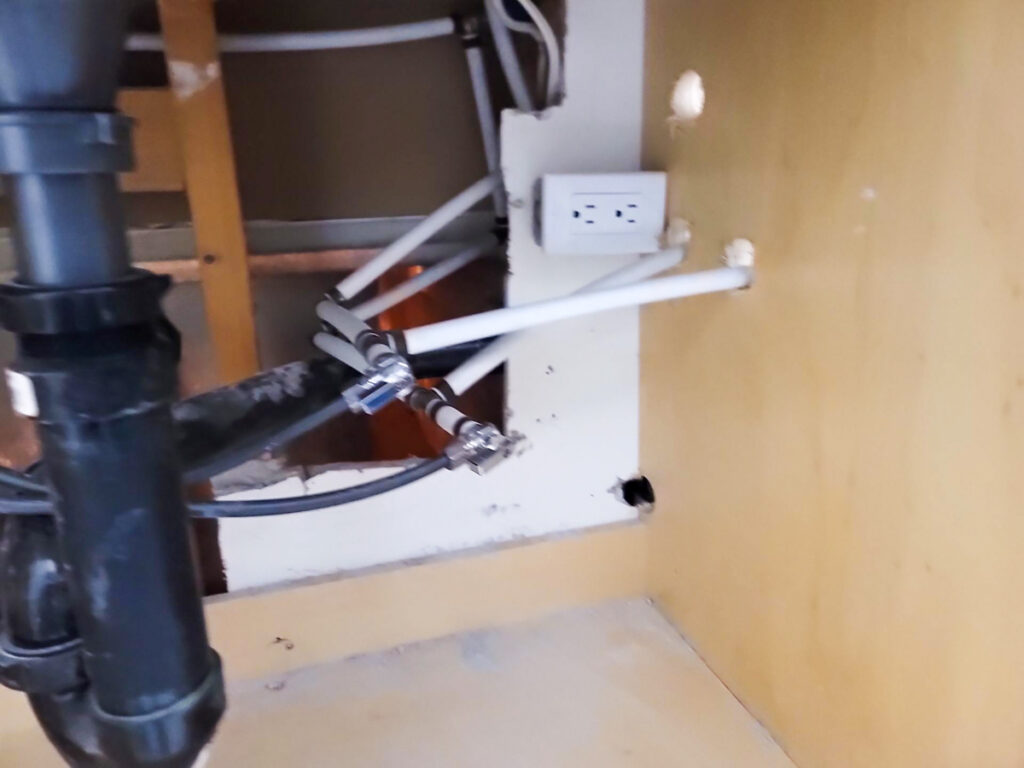

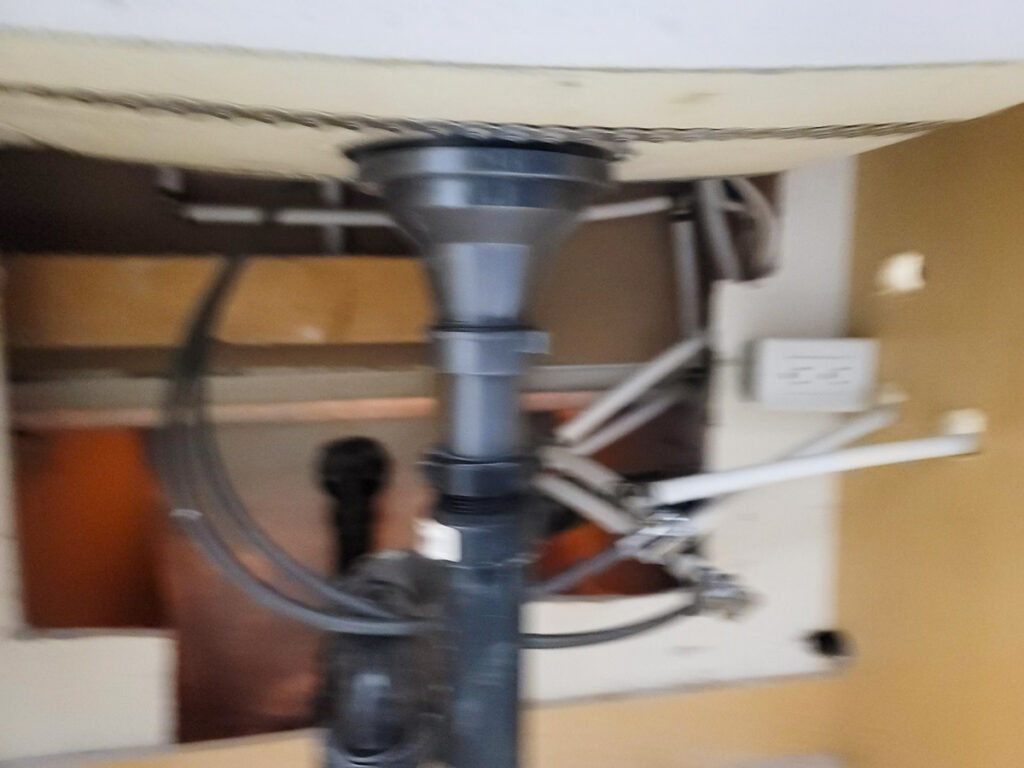

The piping replacement included complete removal of all polybutylene lines and installation of Rehau Class A PEX with UV barrier protection. Every fixture received new Dahl shut-off valves and braided distribution hoses. Brass exterior faucets replaced the original fixtures, and a code-compliant laundry box completed the installation. The professional-grade air scrubber maintained air quality throughout the work, filtering construction dust through four-stage HEPA filtration.

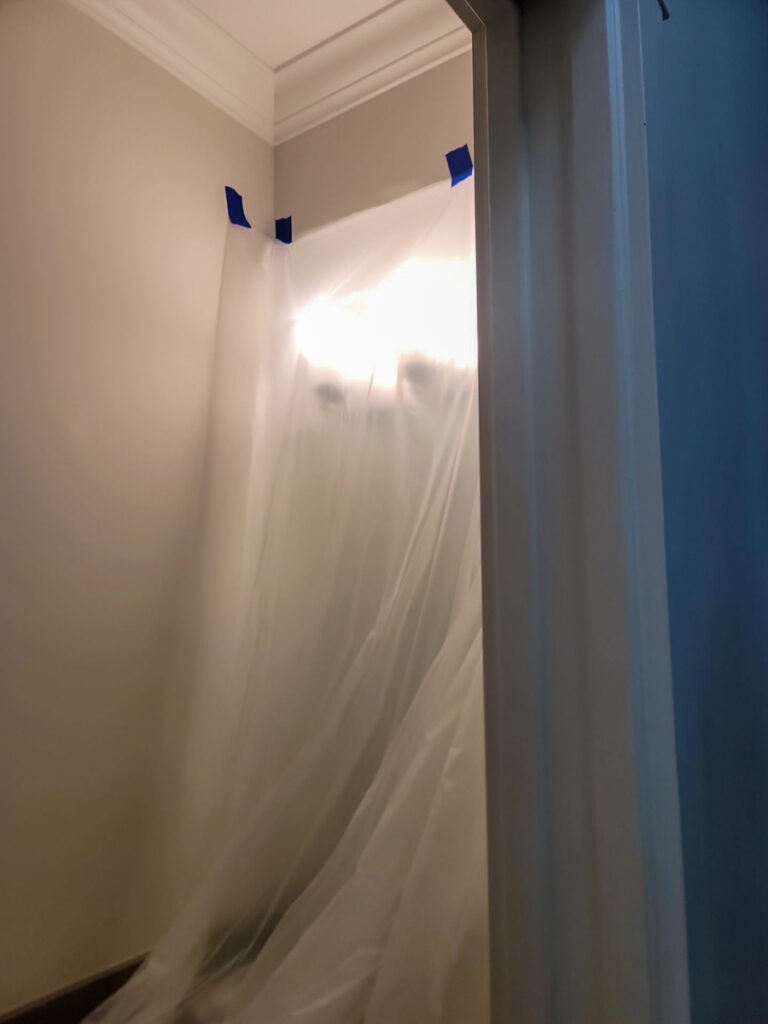

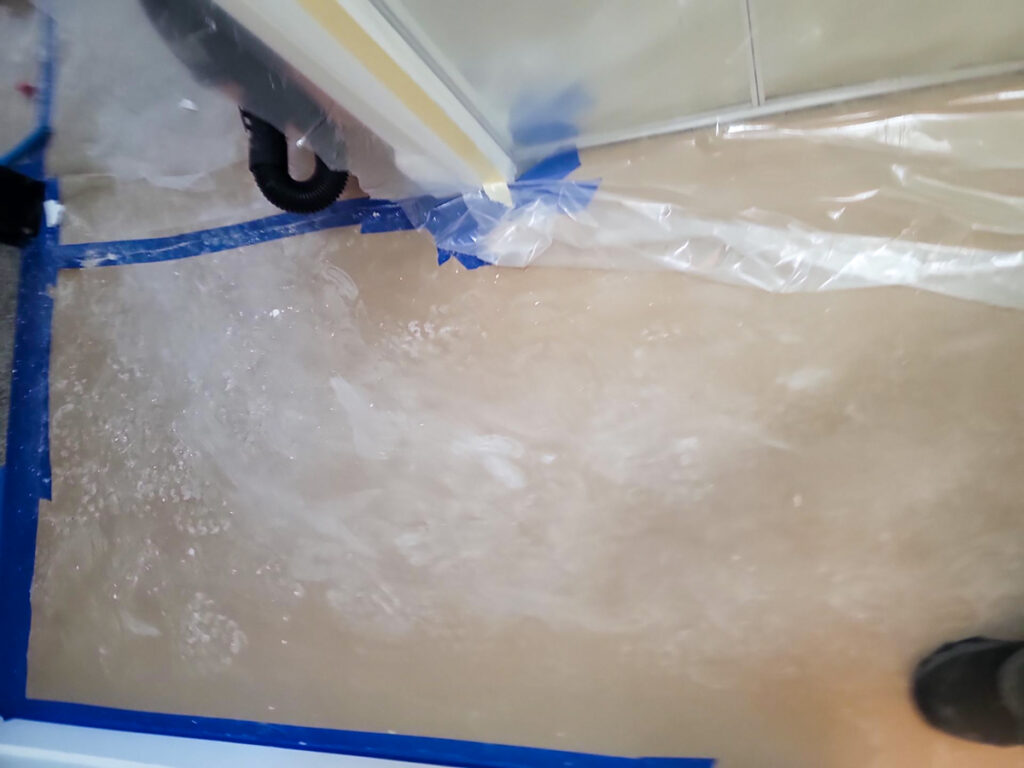

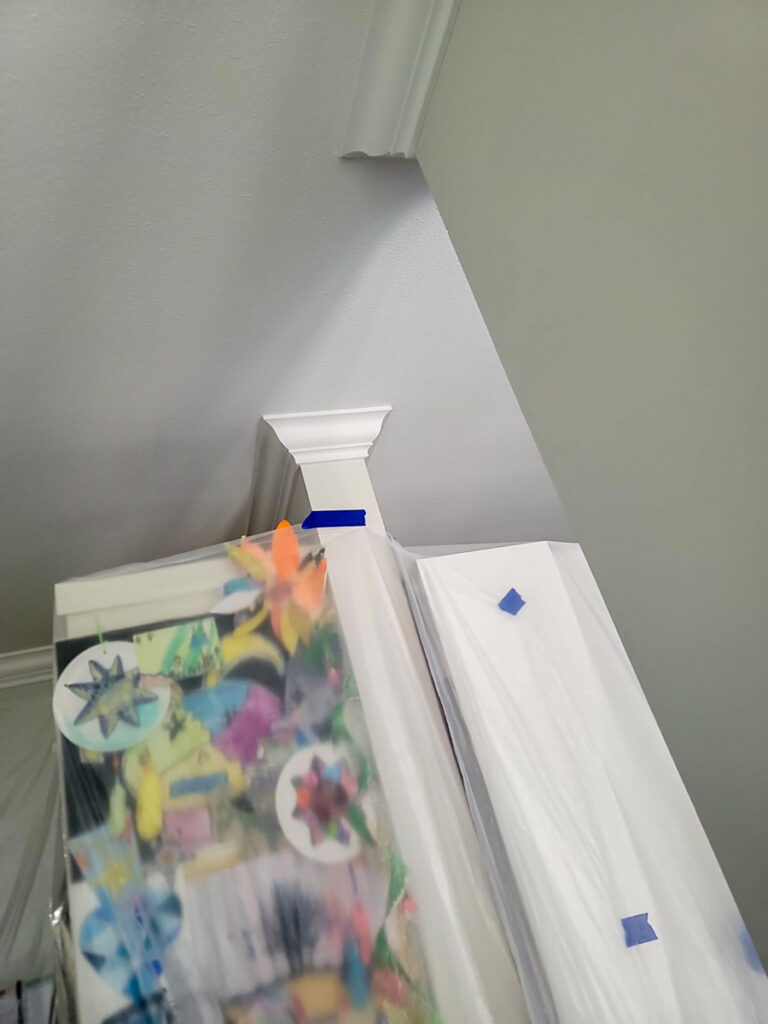

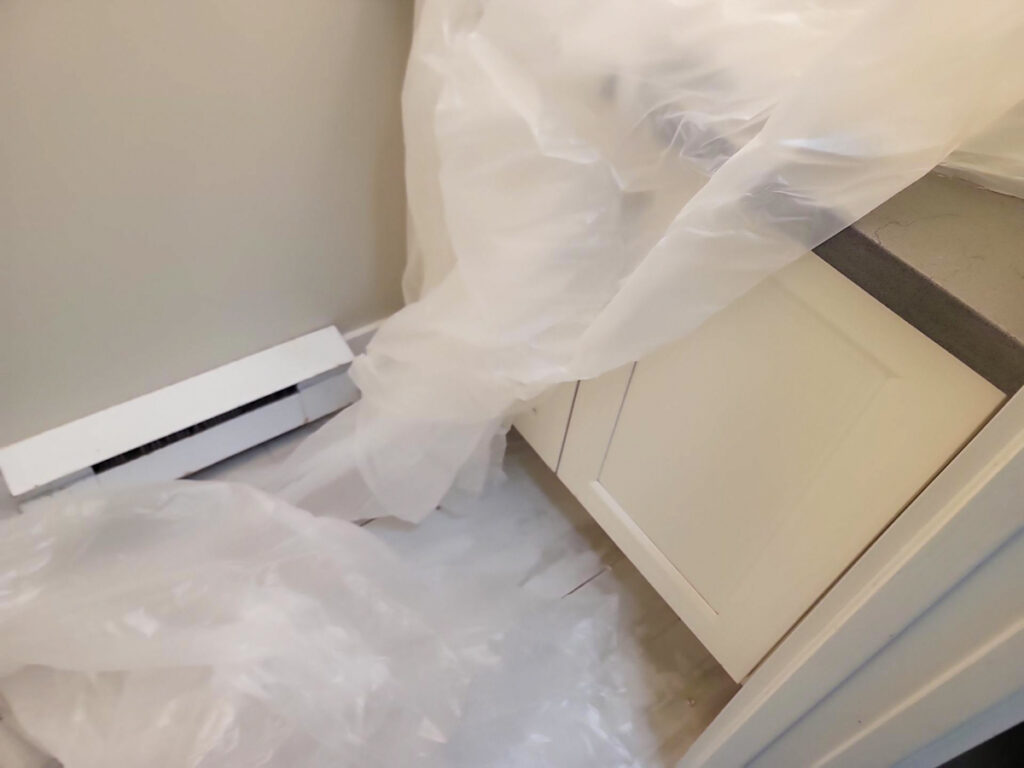

Urban Piping’s site protection protocols applied fully to Eric’s project despite the reduced scope. Ram board protected tile and hardwood surfaces, carpet cling shielded carpeted areas, and light plastic covered furniture in work zones. The basic cleanup service removed all prep materials and construction waste, returning the home to 70-80% of pre-renovation condition. This Poly B Replacement Vancouver project shows that accessible plumbing configurations can significantly reduce both cost and disruption.

Eric became the fourth owner in his townhouse complex to work with Urban Piping, joining neighbors who had completed their projects in preceding weeks. The pattern reflects how word-of-mouth spreads through strata communities—each successful project builds confidence for owners still evaluating their options.

About Ladner Delta BC

Ladner is a historic community within the City of Delta, located where the Fraser River meets the Strait of Georgia in Metro Vancouver’s southern reaches. Originally established as a fishing village in 1868, Ladner developed around the salmon industry before evolving into the residential community it is today. The area retains its village character with heritage buildings along the main streets while residential neighborhoods extend into surrounding areas.

Delta encompasses three distinct communities: Ladner, Tsawwassen, and North Delta. Together these areas form what residents often call “South Delta,” distinguished from North Delta by geography and development patterns. Ladner sits between agricultural land and the river, giving the community a quieter, more removed feeling compared to Vancouver’s urban density just thirty minutes north.

The townhouse developments throughout Ladner reflect construction patterns from the 1970s through 1990s—precisely the era when polybutylene piping was standard in residential construction. These attached housing communities present both challenges and opportunities for Poly B replacement: shared walls require coordination, but concentrated ownership means word-of-mouth spreads quickly when one owner’s project succeeds.

Eric’s complex exemplifies this dynamic. Located on 57 Street in Ladner’s established residential area, the townhouse community has seen multiple units complete Poly B replacement through Urban Piping. The geographic concentration means crews familiar with the complex’s construction can work efficiently, and owners benefit from seeing completed projects in neighboring units before committing to their own.

When Piping-Only Replacement Makes Sense in Ladner Townhouses

Not every Poly B replacement requires full remediation with drywall restoration. Eric’s Ladner townhouse demonstrated conditions that allowed for “piping only” scope—complete plumbing replacement without the drywall cutting and restoration that most projects require. Understanding when this efficient approach applies helps townhouse owners evaluate their specific situations.

Accessible plumbing configurations occur when pipes run through areas that don’t require wall penetration to reach. Unfinished basements, exposed mechanical rooms, accessible crawl spaces, or previous renovations that left plumbing exposed can all create conditions where new PEX lines can be installed without cutting finished surfaces. In townhouse settings, end units or specific floor plans sometimes offer better access than interior configurations.

The cost difference is substantial. Eric’s piping-only project came in well below the full remediation costs his neighbors paid for their units. The savings reflect eliminated labor for drywall cutting, patching, taping, mudding, texturing, and painting—work that can represent forty percent or more of a full remediation project.

For owners considering their options, a professional assessment determines which scope applies. Urban Piping evaluates each unit individually, identifying accessible runs and recommending the appropriate approach. In strata communities where multiple units are considering replacement, this individualized assessment ensures each owner pays only for the scope their specific unit requires.

Strata Community Momentum in Ladner Townhouse Complexes

Eric’s project marked the fourth Poly B replacement Urban Piping completed in his Ladner townhouse complex during the same period. This concentration illustrates how strata communities often approach infrastructure upgrades—not through mandated building-wide projects, but through organic word-of-mouth as individual owners observe their neighbors’ experiences.

The pattern typically begins with one owner who researches Poly B risks and decides to act. Their successful project becomes visible to neighbors—they see the Urban Piping van, notice the work being done, and eventually ask questions. The first owner’s experience answers the concerns that keep others hesitant: How long does it take? How much disruption? What does the finished result look like?

Each subsequent project reinforces confidence. By the time Eric scheduled his assessment, three neighbors had already completed their replacements. He could ask them directly about their experiences, see their finished results, and make his decision with real-world validation rather than relying solely on contractor promises.

For Urban Piping, this community concentration creates operational efficiencies. Crews become familiar with the complex’s construction patterns, access points, and specific characteristics. The on-site project manager maintains relationships with strata council representatives. Material deliveries can be coordinated across multiple projects. These efficiencies benefit all participating owners while ensuring consistent quality across every unit.

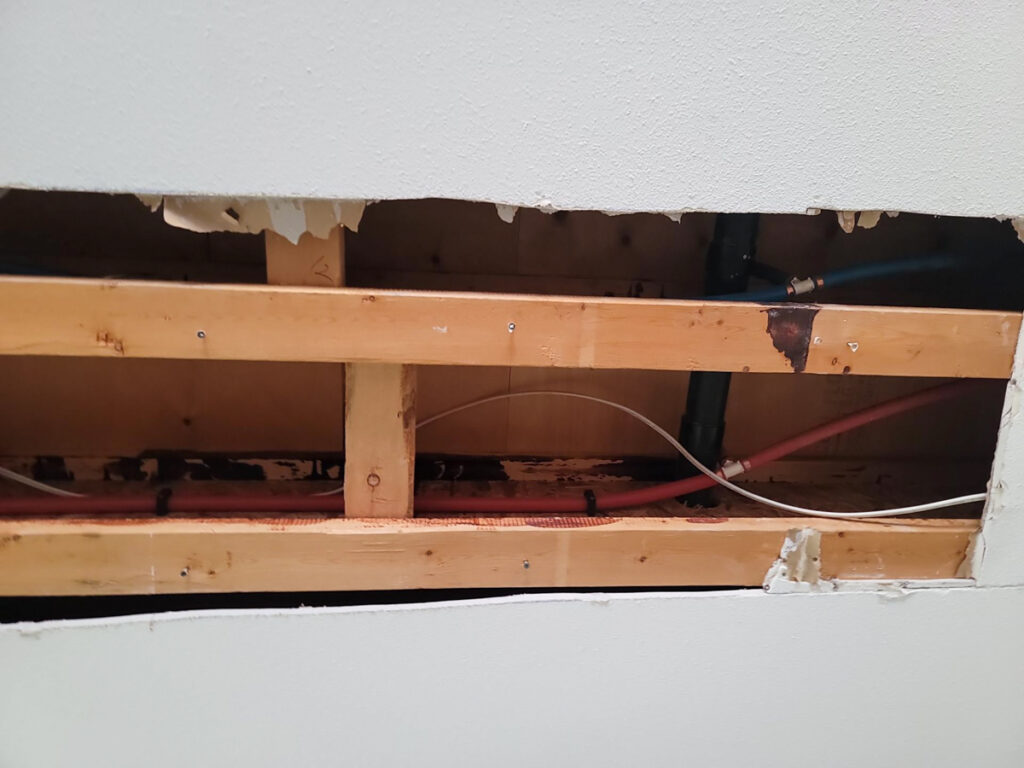

Ladner Townhouse Project Photos

Urban Piping documents the work completed on every job site. Below are the project photos from Eric’s Ladner townhouse piping-only Poly B replacement. This project showcases the meticulous process of replacing outdated piping with reliable materials. Homeowners should be aware of the potential issues associated with aging systems, particularly when finding Poly B in your Vancouver home. The replacement not only improves the plumbing integrity but also enhances the overall value and safety of the property.