Six Units Create Critical Mass for Ladner Townhouse Complex

When Geeta scheduled her Poly B plumbing replacement, she became the sixth owner in her Ladner townhouse complex to work with Urban Piping within the same period. Her “piping only” project joined a growing list of neighbors who had addressed their polybutylene—some through full remediation, others through efficient piping-focused scopes like hers. The concentrated participation transformed individual home improvements into something approaching a building-wide infrastructure upgrade.

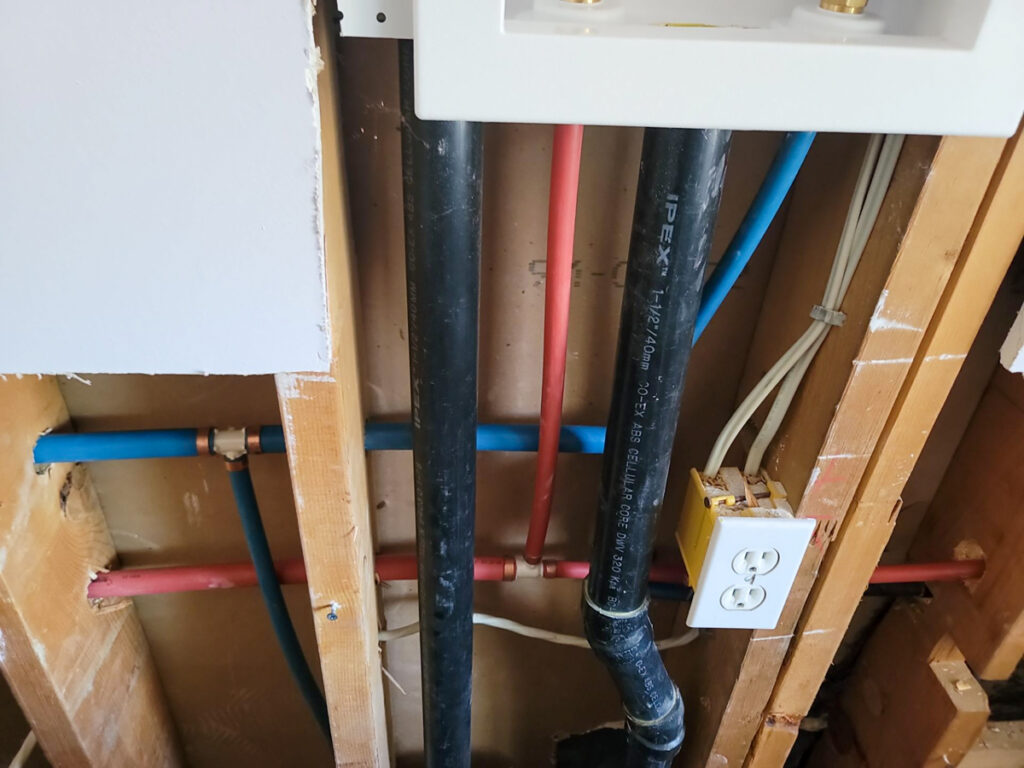

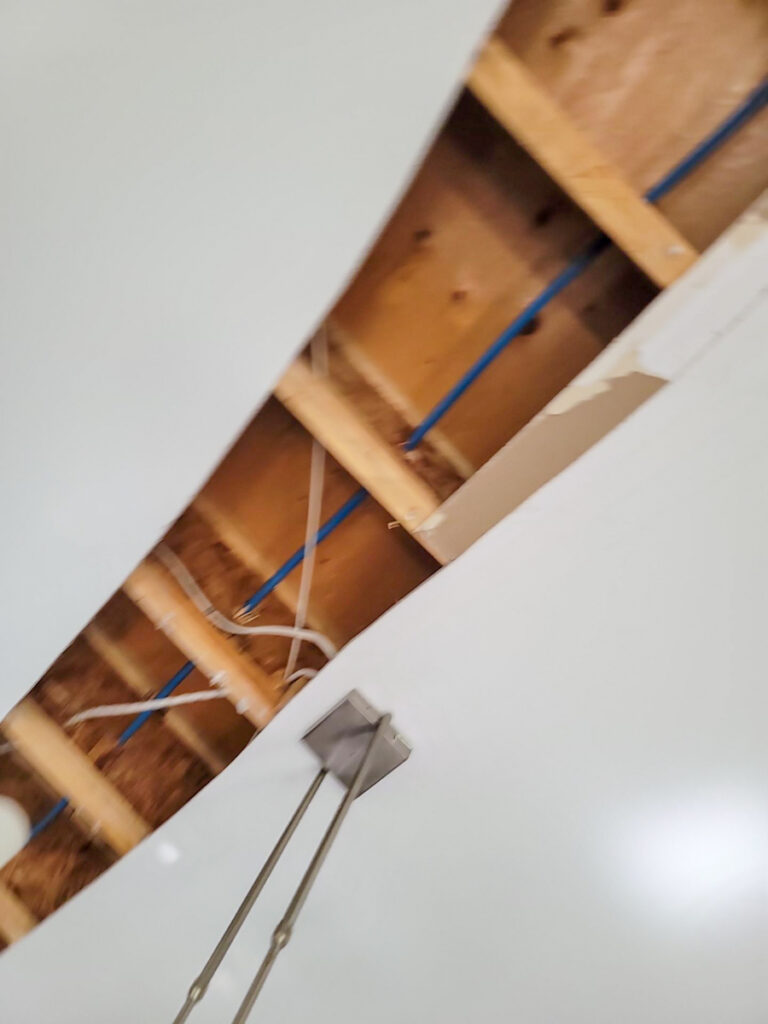

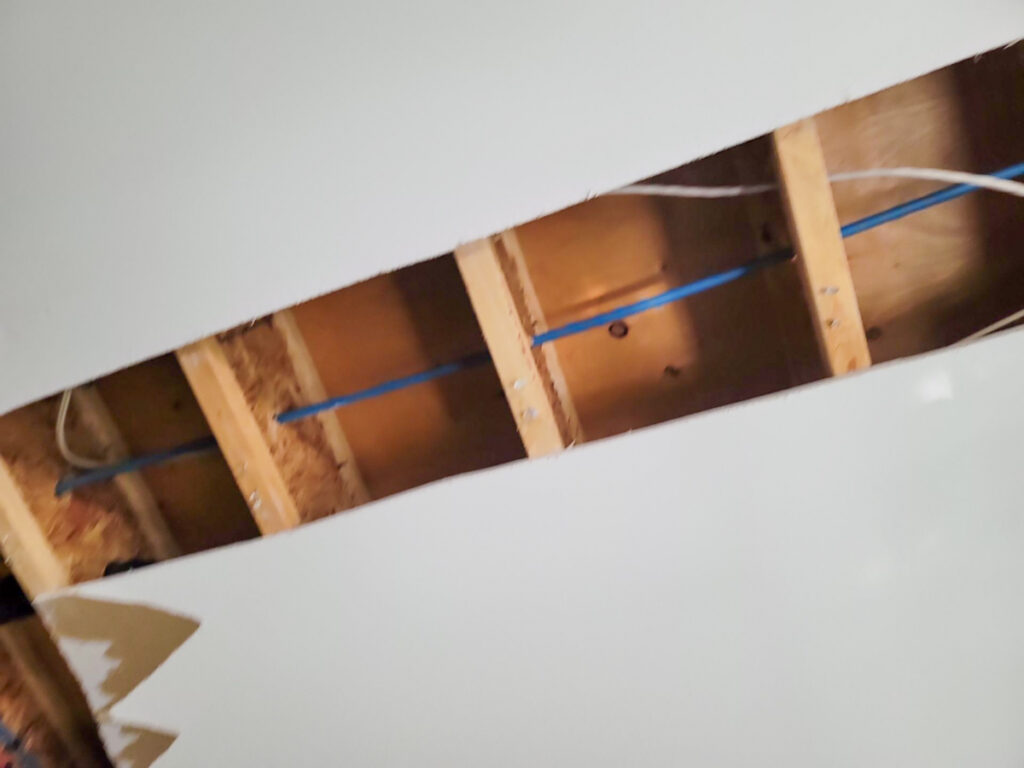

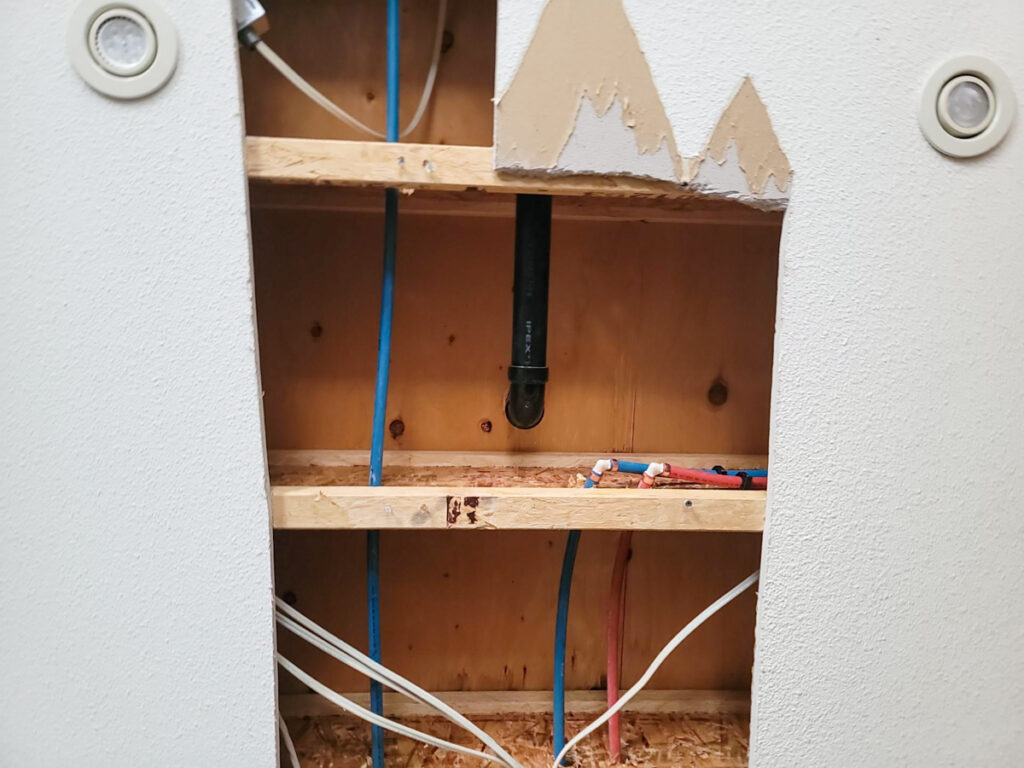

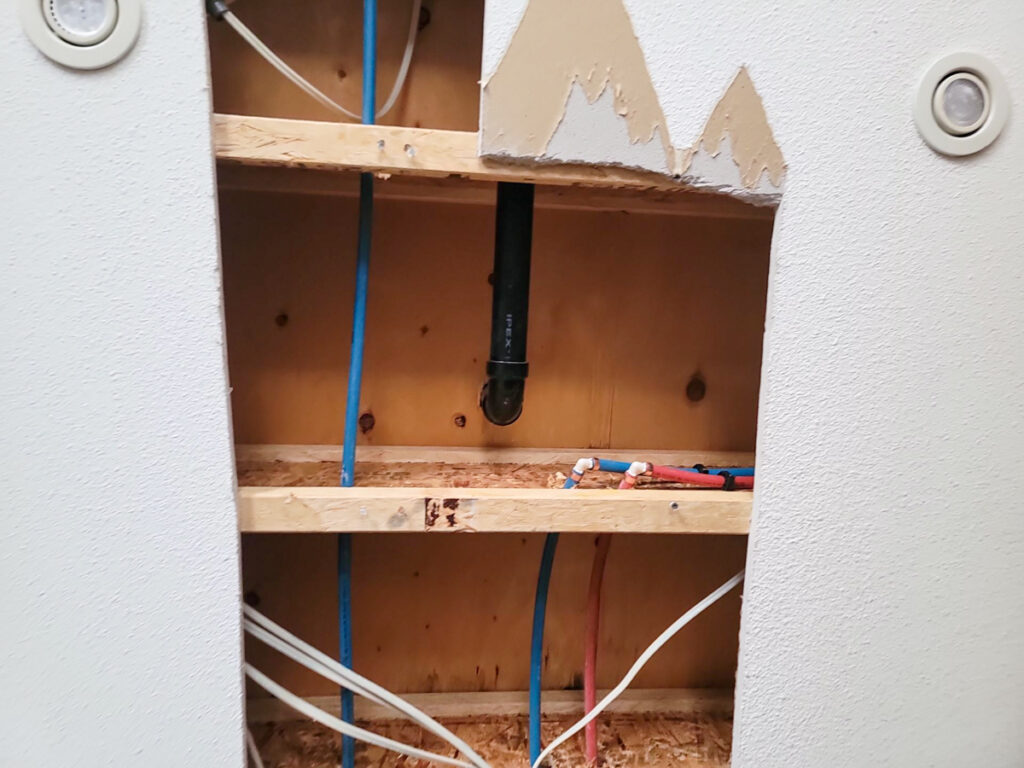

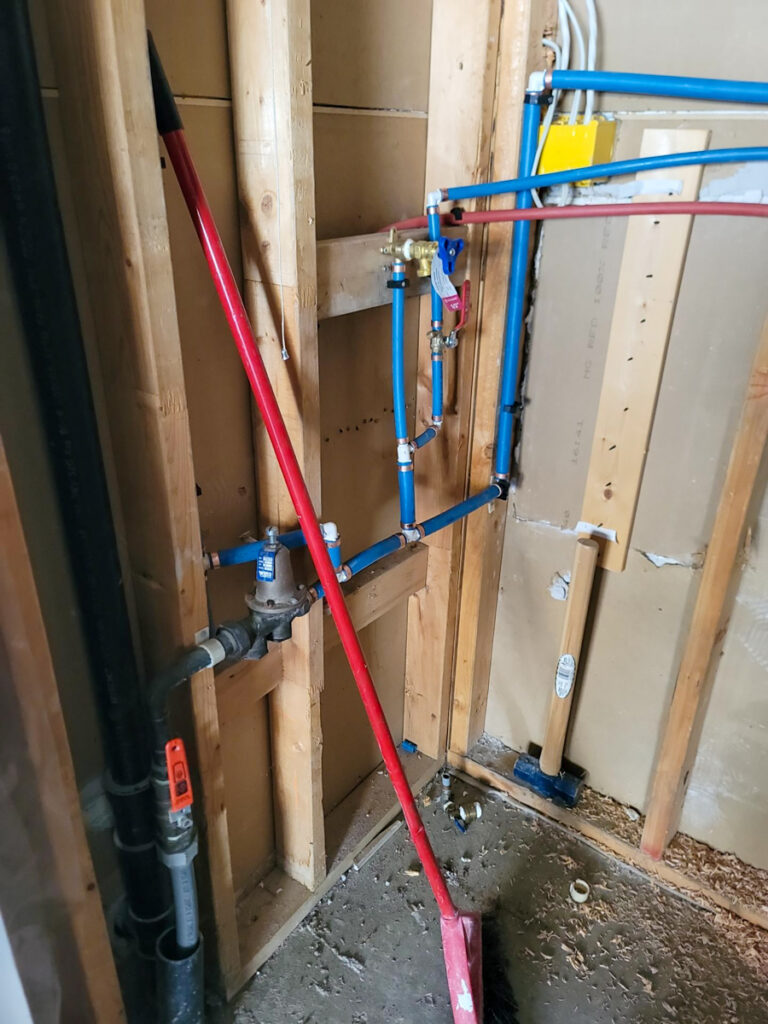

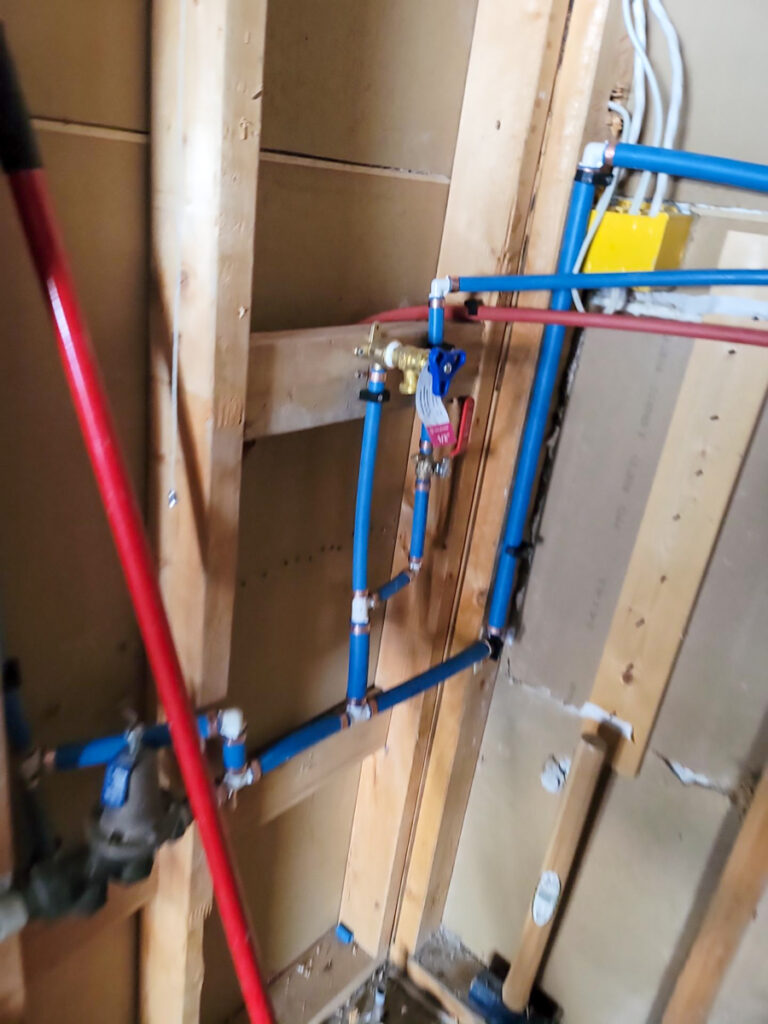

Geeta’s unit featured accessible plumbing that allowed complete replacement without extensive drywall work. The scope included removal of all polybutylene lines and installation of Rehau Class A PEX with UV barrier protection. Every fixture received new Dahl shut-off valves and braided distribution hoses. Brass exterior faucets and a code-compliant laundry box completed the installation. The professional-grade air scrubber maintained indoor air quality throughout.

Site protection protocols safeguarded Geeta’s home during the work. Ram board covered tile and hardwood surfaces, professional-grade carpet liner protected high-traffic areas, and light plastic shielded furniture in work zones. The basic cleanup removed all construction waste and prep materials, returning the home to 70-80% of pre-renovation condition—though it’s worth noting that final cleanliness depends partly on starting conditions. When crews arrive to a cluttered space, they can only do so much to restore it afterward.

This Poly B Replacement Vancouver project demonstrates how organic community momentum can achieve results that formal strata mandates often struggle to accomplish. No building-wide assessment was required. No special levy needed approval. Individual owners simply observed their neighbors’ successful projects and made their own decisions—resulting in six units completing Poly B replacement within months of each other. This organic approach not only fosters a sense of community but also encourages informed decision-making among homeowners. To help others navigate similar situations, here are some valuable Vancouver condo Poly B replacement tips: seek recommendations from neighbors, consult with trusted contractors, and consider group purchasing power to lower costs. By sharing experiences and resources, communities can effectively address shared challenges and enhance their living environments.

About Ladner Delta BC

Ladner is a historic community within the City of Delta, established as a fishing village in 1868 where the Fraser River meets Georgia Strait. Delta encompasses three communities—Ladner, Tsawwassen, and North Delta—with Ladner and Tsawwassen forming “South Delta.”

The townhouse developments throughout Ladner reflect construction from the 1970s through 1990s, precisely when polybutylene piping was standard. These attached housing communities present coordination challenges but also concentrate decision-makers who can observe each other’s experiences directly.

Geeta’s complex on 57 Street demonstrates how strata communities can systematically address aging infrastructure without formal mandates. Six units completing Poly B replacement through the same contractor created operational efficiencies benefiting all participants. Crews familiar with the building worked efficiently across units while the on-site project manager maintained consistent communication with owners and strata representatives.

The setting between agricultural land and the Fraser River gives Ladner a quieter character than Vancouver thirty minutes north.

Why Some Ladner Units Need Full Remediation While Others Don’t

Geeta’s “piping only” scope cost roughly half what neighbors paid for full remediation—not because her plumbing system was smaller, but because her unit’s configuration allowed access without cutting finished walls. This variation within a single complex illustrates why cookie-cutter pricing rarely applies to Poly B replacement, even in buildings where units appear identical from the outside.

Townhouse construction creates different access conditions unit by unit. End units may have mechanical rooms accessible from garages. Some floor plans route plumbing through unfinished spaces. Previous renovations in specific units might have exposed pipes that remain accessible. The result is that two adjacent units with identical square footage can require dramatically different scopes.

In Geeta’s complex, the pattern emerged clearly: four units required full remediation with drywall restoration, while two units—including Geeta’s—qualified for piping-only replacement. The assessment process identified these differences before work began, ensuring each owner paid only for the scope their specific unit required.

For strata communities evaluating Poly B replacement, this variation matters for planning. Building-wide cost estimates should account for the range of likely scopes rather than assuming uniform pricing. Some owners will face higher costs; others will benefit from accessible configurations. Understanding this before the first unit begins helps set appropriate expectations across the ownership group. Additionally, conducting a thorough analysis, such as the Delta strata Poly B case study, can provide valuable insights into the specific challenges and opportunities associated with the replacement process. This case study can serve as a benchmark for similar communities, highlighting successful strategies and potential pitfalls. Armed with this knowledge, strata councils can make informed decisions that align with the unique needs of their community.

From First Project to Critical Mass in One Ladner Complex

The trajectory from one owner’s decision to six completed projects followed a predictable pattern. Brad’s unit was first—he researched Poly B risks, evaluated contractors, and committed to replacement. His successful project became visible to neighbors who saw the work happening and eventually asked questions.

The second and third owners benefited from Brad’s experience. They could ask him directly about the process, see his finished results, and make decisions with real-world validation. Each subsequent project reinforced community confidence. By the time Geeta scheduled her assessment, five neighbors had already completed their replacements or had work underway.

Six units represents meaningful critical mass for a townhouse complex. The building now has majority participation in Poly B replacement, a new main shutoff valve serving all units, and an established contractor relationship. Remaining owners considering replacement can leverage this foundation—crews know the building, the project manager has strata relationships, and completed units demonstrate results.

The organic approach achieved what formal strata processes often struggle to accomplish. No contentious special general meetings debated mandatory assessments. No owners felt forced into unwanted expenditures. Individual decision-making, informed by neighbor experiences, produced collective infrastructure improvement that benefits the entire complex.

Ladner Community Project Photos

A Note on Homeowner Preparation: Urban Piping recommends that homeowners prepare their space before crews arrive. Clearing clutter from work areas, moving personal items away from walls where plumbing access is needed, and ensuring pathways remain unobstructed helps our team work efficiently and safely. When crews must work around obstacles, project timelines can extend and the risk of accidental damage to personal belongings increases. A few hours of preparation before your scheduled start date helps ensure the smoothest possible experience for everyone involved.

Urban Piping documents the work completed on every job site. Below are the project photos from Geeta’s Ladner piping-only Poly B replacement.